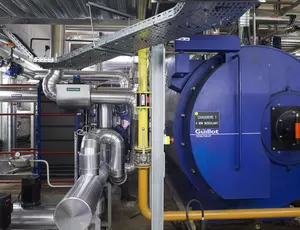

Corrosion, scaling and fouling can reduce the operating efficiency of your boiler and compromise the performance of all the systems connected to the water and steam circuits, causing downtimes and increasing the total cost of operation. HydrexⓇ chemical solutions for boiler water treatment combine selected formulations, equipment, real-time monitoring and service to prevent these situations from occuring.

To define the optimal conditioning strategy, the Hydrex boiler water treatment program starts with a risk assessment to evaluate make-up water and feedwater quality, system configuration (pretreatment, boiler characteristics, pressure, norms, etc.) and operating conditions, taking all the parameters and constraints into consideration. The objectives of the program are:

To prevent the formation of deposits that could damage the heat transfer and to ensure the long-term protection of assets.

To fix the pH conditions and remove any dissolved oxygen – a constant threat to boiler feedwater systems, internal boilers and condensate systems.

To reach sufficient steam quality for the targeted use (no carry-over nor silica).

To get non-aggressive condensates with respect to return piping.

To optimize the consumption of chemicals, energy and water by using simulation tools to calculate the potential savings along with online analyzers to measure and manage performance.

To reach maximum operator safety and sustainability by using the most environmentally friendly techniques.

In addition to boiler water treatment programs, our industrial water treatment specialists can provide you with efficient solutions to pretreat boiler feedwater such as:

Reverse osmosis to increase concentration rates and thus reduce energy consumption.

Softeners for low-pressure systems.

Demineralization for high-pressure systems.

Discover in our case study how choosing the right water treatment chemical partner is a key element for an optimal management of boilerhouses